Low MOQ for Cold Room Panel Thickness - 20-1000cbm Freezer Room For Seafood – LINBLE

Low MOQ for Cold Room Panel Thickness - 20-1000cbm Freezer Room For Seafood – LINBLE Detail:

Cold Room Description

Seafood freezer room are mainly used to store various seafood and aquatic products. The temperature range of seafood freezer room is generally between -18 degrees and -30 degrees, which can greatly prolong the preservation time of seafood and keep the original quality and seafood taste. Seafood freezer room is mainly used in aquatic product wholesale markets, seafood processing plants, frozen food factories and other industries.

Cold Room Details

Minimize the opening time for employees to enter the cold storage. Cold storage doors should be closed. Unfrozen seafood cannot be stored in a low-temperature freezer to minimize heat entering the freezer. If the temperature of the low-temperature freezer rises above -8°C, seafood products should be re-stored in the low-temperature freezer after freezing.

Aquatic products that do not meet the quality requirements cannot be stored in cold storage. Seafood should be stacked neatly and tightly, and packaged and unpacked products should be stored separately.

Cold Room Structure

Cold room consists of insulated panels(PUR/PIR sandwich panel), cold room door(hinged door/sliding door/swing door), condensing unit, evaporator (air cooler),temperature controller box, air curtain, copper pipe, expansion valve and other fittings.

Cold Room Applications

Cold room is widely used in food industry, medical industry, and other related industries.

In food industry, cold room is usually used in food processing factory, slaughterhouse, fruit and vegetable warehouse,supermarket,hotel, restaurant, etc.

In medical industry, cold room is usually used in hospital, pharmaceutical factory, blood center, gene center, etc.

Other related industries, such as chemical factory, laboratory, logistics center, they also need cold room.

Seafood cold storage construction requirements.

1. The cold storage panel is generally made of polyurethane and 304 stainless steel on both sides , which has good sealing performance, light weight and convenient installation.

2. Cold storage refrigeration units generally use condensing parallel units to meet the cooling capacity requirements of seafood cold storage.

3. The temperature control system can set the appropriate temperature and humidity according to the requirements.

How to Customize Cold Room

1.What is the application of the cold room?

PU sandwich panel thick and surface material are decided by this. For example, cold room for seafood storing, we use panel with 304 stainless steel, which is corrosion resistant and has long service life.

2.What is cold room size? Length*Width*Height

We calculate panel quantity,choose condensing unit and evaporator model according to cold room size.

3.Which country will the cold room be located in? How about the climate?

Power supply is decided by country. If the temperature is high , we need to choose condenser with bigger cooling area.

Following are some standard sizes for chiller room and freezer room. Welcome to check.

Cold Room Parameter

|

|

Changxue |

|

Size |

Customized |

|

Temperature |

-50°C to 50 °C |

|

Voltage |

380V, 220V or Customized |

|

Main parts |

PUR/PIR sandwich panel |

|

Cold room door |

|

|

Condensing unit——Bitzer, Emerson, GREE, Frascold. |

|

|

Air cooler——GREE, Gaoxiang, Jinhao, etc. |

|

|

Fittings |

Valves, copper pipe, thermal insulation pipe, wire, PVC pipe PVC curtain, LED light |

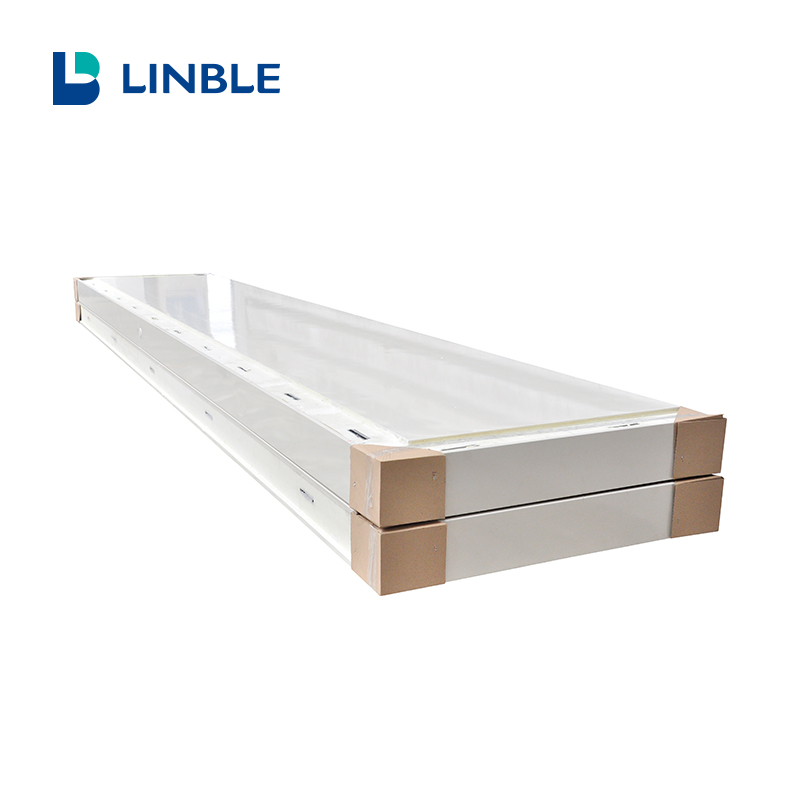

Cold Room Panel

We use fluoride-free material, it is more environment-friendly. Our cold room panels can reach fireproof level B2/B1

Polyurethane panel is foamed by high pressure with density of 38-42 kg/m3. So the thermal insulation will be good.

Cold Room Door

We have different types of cold room door, such as hinged door, sliding door, free door,swing door and other types of doors according to your requirement.

Condensing Unit

We use the world famous compressor like Bitzer, Emerson, Refcomp, Frascold and etc.

It is easy to operate the automatic high-precision digital controller with high efficiency.

Evaporator

Air coolers has DD series, DJ series, DL series model.

DD series is suitable for medium temperature;

DJ series is suitable for low temperature;

DL series is suitable for high temperature.

For blast freezer, we also use aluminum pipe

Temperature Controller Box

Standard Functions:

Overload protection

Phase sequence protection

High and low pressure protection

Short circuit alarm

Automatic temperature control & automatic defrosting

Another customized functions can be also added, like humidity.

How to Install a Cold Room?

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create more value for our customers with our rich resources, advanced machinery, experienced workers and excellent services for Low MOQ for Cold Room Panel Thickness - 20-1000cbm Freezer Room For Seafood – LINBLE , The product will supply to all over the world, such as: Greece, Auckland, Malawi, Over the years, with high-quality solutions, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We offer high quality product and competitive price, welcome the regular and new customers cooperate with us!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!